/***************************************************************************************

* Lin_Enc_01.ino 04-29-2014 unix_guru at hotmail.com @unix_guru on twitter

* http://arduino-pi.blogspot.com

*

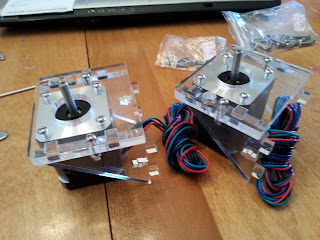

* This sketch allows you to run two salvaged printer carriages for X/Y axis using their

* linear encoder strips for tracking.

* Both interrupt routines are below, but for the sake of demonstration, I've only set up

* the X-AXIS for now.

*

*****************************************************************************************/

#include <Wire.h>

#include <Adafruit_MotorShield.h>

#include "utility/Adafruit_PWMServoDriver.h"

#define frontstop = 100 // Right most encoder boundary

#define backstop = 3600 // Left most encoder boundary

// Create the motor shield object with the default I2C address

Adafruit_MotorShield AFMS = Adafruit_MotorShield();

// Select which 'port' M1, M2, M3 or M4. In this case, M1

Adafruit_DCMotor *myMotor = AFMS.getMotor(1);

const int encoder1PinA = 2; // X-AXIS encoder 1 on pins 2 and 4

const int encoder1PinB = 4;

volatile int encoder1Pos = 0;

const int encoder2PinA = 3; // Y-AXIS encoder 2 on pins 3 and 5

const int encoder2PinB = 5;

volatile int encoder2Pos = 0;

boolean CarriageDir = 0; // Carriage Direction '0' is Right to left

byte spd = 220; // Carriage speed from 0-255

int newpos = 0; // Taget position for carriage

int posrchd = 1; // Flag for target reached

int Pos1, Pos2;

void setup() {

Serial.begin(115200);

Serial.println("Linear Encoder Test 04-29-2014");

AFMS.begin(); // Set up Motors

myMotor->run(BACKWARD); // Bring carriage to home position.

myMotor->setSpeed(spd);

delay(100);

myMotor->run(FORWARD); // Bring carriage to home position.

myMotor->setSpeed(0);

attachInterrupt(0, doEncoder1, CHANGE); // encoder pin on interrupt 0 (pin 2)

// attachInterrupt(1, doEncoder2, CHANGE); // encoder pin on interrupt 1 (pin 3)

randomSeed(analogRead(0));

}

void loop() {

static int oldPos1, oldPos2;

uint8_t oldSREG = SREG;

uint8_t i;

cli();

Pos1 = encoder1Pos;

Pos2 = encoder2Pos;

SREG = oldSREG;

if(Pos1 != oldPos1){

Serial.print("Encoder 1=");

Serial.println(Pos1,DEC);

oldPos1 = Pos1;

}

if(Pos2 != oldPos2){

Serial.print("Encoder 2=");

Serial.println(Pos2,DEC);

oldPos2 = Pos2;

}

//sweep_carriage();

if(posrchd) { // If target has been reached clear flag, and get new target

newpos = random(200,3500);

posrchd = 0;

}

posrchd = go_to_target(newpos);

}

/***************************************************************************************

The following code was taken from http://forum.arduino.cc/index.php?topic=41615.20;wap2

to utilize the fast port based encoder logic. Thank you Lefty!

please go there for a full explanation of how this works. I have truncated the comments

here for brevity.

***************************************************************************************/

void doEncoder1() { // ************** X- AXIS ****************

if (PIND & 0x04) { // test for a low-to-high interrupt on channel A,

if ( !(PIND & 0x10)) { // check channel B for which way encoder turned,

encoder1Pos = ++encoder1Pos; // CW rotation

PORTD = PIND | 0x40; // set direction output pin to 1 = forward,

}

else {

encoder1Pos = --encoder1Pos; // CCW rotation

PORTD =PIND & 0xBF; // Set direction output pin to 0 = reverse,

}

}

else { // it was a high-to-low interrupt on channel A

if (PIND & 0x10) { // check channel B for which way encoder turned,

encoder1Pos = ++encoder1Pos; // CW rotation

PORTD = PIND | 0x40; // Set direction output pin to 1 = forward,

}

else {

encoder1Pos = --encoder1Pos; // CCW rotation

PORTD =PIND & 0xBF; // Set direction output pin to 0 = reverse,

}

}

PORTD = PIND | 0x80; // digitalWrite(encoderstep, HIGH); generate step pulse high

PORTD = PIND | 0x80; // digitalWrite(encoderstep, HIGH); add a small delay

PORTD = PIND & 0x7F; // digitalWrite(encoderstep, LOW); reset step pulse

} // End of interrupt code for encoder #1

void doEncoder2(){ // ************** X- AXIS ****************

if (PIND & 0x08) { // test for a low-to-high interrupt on channel A,

if (!(PIND & 0x20)) { // check channel B for which way encoder turned,

encoder2Pos = ++encoder2Pos; // CW rotation

PORTB = PINB | 0x01; // Set direction output pin to 1 = forward,

}

else {

encoder2Pos = --encoder2Pos; // CCW rotation

PORTD =PIND & 0xFE; // Set direction output pin to 0 = reverse,

}

}

else { // it was a high-to-low interrupt on channel A

if (PIND & 0x20) { // check channel B for which way encoder turned,

encoder2Pos = ++encoder2Pos; // CW rotation

PORTB = PINB | 0x01; // Set direction output pin to 1 = forward,

}

else {

encoder2Pos = --encoder2Pos; // CCW rotation

PORTB =PINB & 0xFE; // Set direction output pin to 0 = reverse,

}

}

PORTB = PINB | 0x02; // digitalWrite(encoder2step, HIGH); generate step pulse high

PORTB = PINB | 0x02; // digitalWrite(encoder2step, HIGH); used to add a small delay

PORTB = PINB & 0xFD; // digitalWrite(encoder2step, LOW); reset step pulse

} // End of interrupt code for encoder #2

/***************************************************************************************

go_to_target() determines the distance and direction from current position to target

position, then maps speed to decellerate close to the target so as not to overshoot.

***************************************************************************************/

int go_to_target(int target)

{

int temp = 0;

int delta = abs(Pos1-target); // Distance to target

spd = map(delta,3600,0,255,150); // Decellerate as you get closer

if(target < 3600 && target > 100) {

if(Pos1 < target) {

myMotor->run(FORWARD);

myMotor->setSpeed(spd);

temp = 0;

} else if(Pos1 > target) {

myMotor->run(BACKWARD);

myMotor->setSpeed(spd);

temp = 0;

} else temp =1;

}

return temp;

}

/***************************************************************************************

sweep_carriage() is just a test routine to track back and forth testing overshoot.

I will likely remove it soon.

***************************************************************************************/

void sweep_carriage()

{

if(CarriageDir == 0) { // Carriage Moving Right to Left

if (Pos1 < 3600) {

myMotor->run(FORWARD);

if (Pos1 > 3400) {

myMotor->setSpeed(spd-80);

} else myMotor->setSpeed(spd);

} else {

myMotor->setSpeed(0);

CarriageDir = !CarriageDir;

}

} else { // Carriage Moving Left to Right

if (Pos1 > 100) {

myMotor->run(BACKWARD);

if (Pos1 < 300) {

myMotor->setSpeed(spd-80);

} else myMotor->setSpeed(spd);

} else {

myMotor->setSpeed(0);

CarriageDir = !CarriageDir;

}

}

}

And to appease the readers of Hack A Day ....

And to appease the readers of Hack A Day ....