/***************************************************************************************

* Lin_Enc_02.ino 05-12-2014 unix_guru at hotmail.com @unix_guru on twitter

* http://arduino-pi.blogspot.com

*

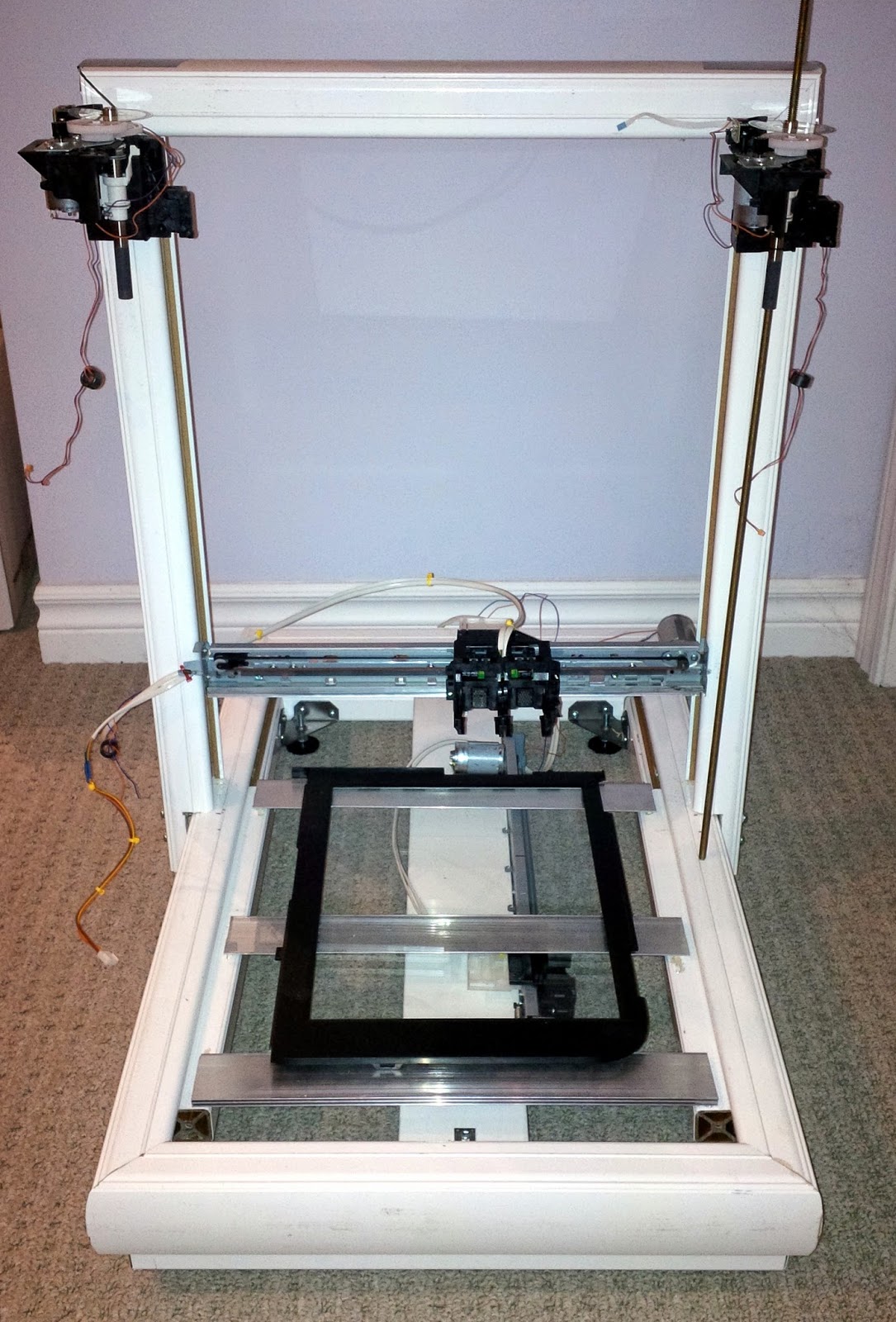

* This sketch allows you to run two salvaged printer carriages for X/Y axis using their

* linear encoder strips for tracking.

* This example uses the Arduino PID Library found at:

* https://github.com/br3ttb/Arduino-PID-Library/archive/master.zip

*

* Hardware Interrupt 0 on Digital pin2 is used to determine X-Axis position

* Hardware Interrupt 1 on Digital pin3 is used to determine Y-Axis position

* PinchangeInterrupt is used to identify the Zero Endstop for X and Y axis

*****************************************************************************************/

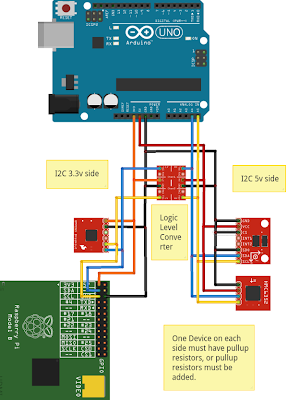

#include <Wire.h>

#include <Adafruit_MotorShield.h>

#include "utility/Adafruit_PWMServoDriver.h"

#include <PID_v1.h>

#include <PinChangeInt.h>

#define frontstop = 100 // Right most encoder boundary

#define backstop = 3600 // Left most encoder boundary

// Create the motor shield object with the default I2C address

Adafruit_MotorShield AFMS = Adafruit_MotorShield();

// Select which 'port' M1, M2, M3 or M4. In this case, M1

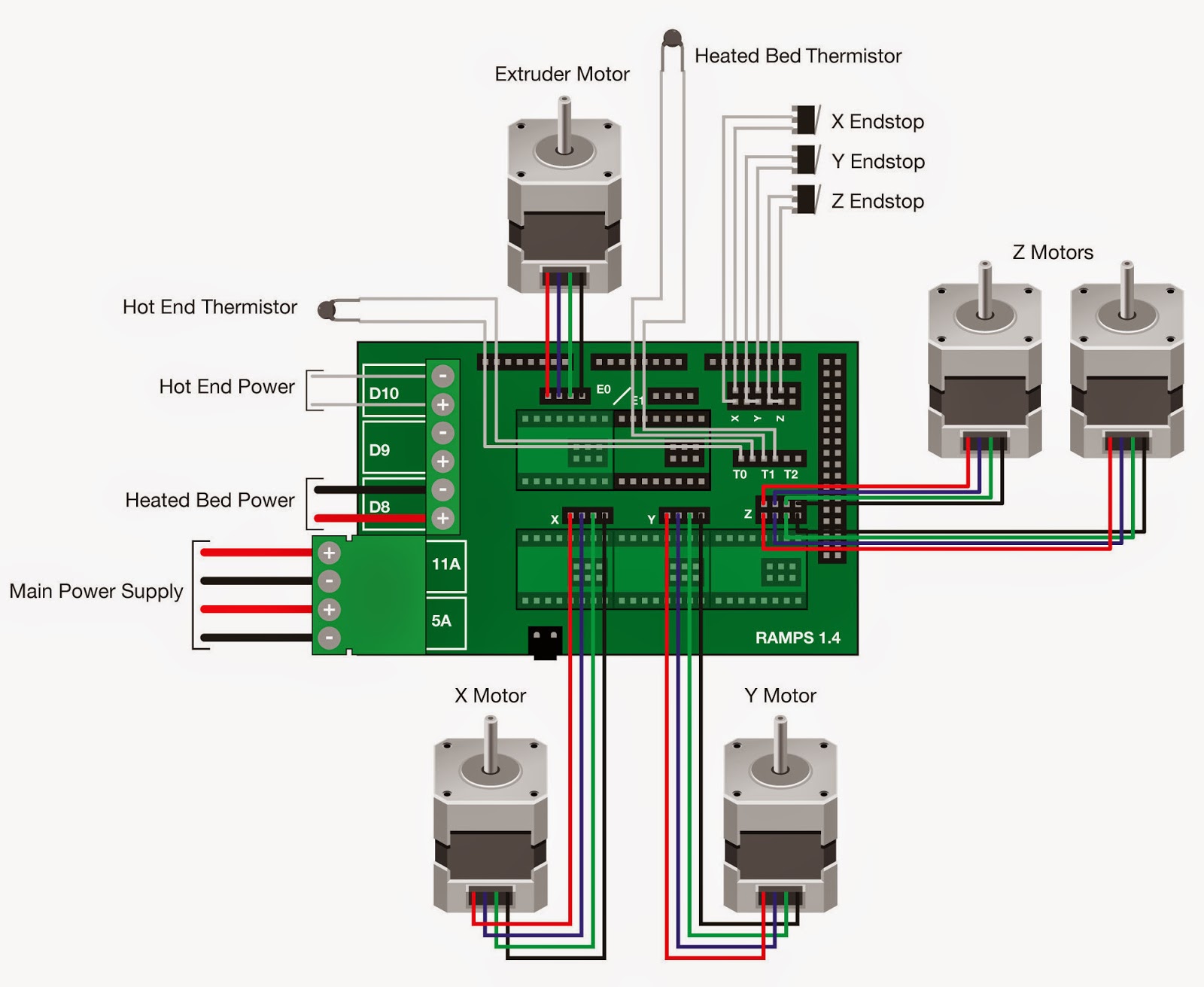

Adafruit_DCMotor *XaxisMotor = AFMS.getMotor(1);

Adafruit_DCMotor *YaxisMotor = AFMS.getMotor(2);

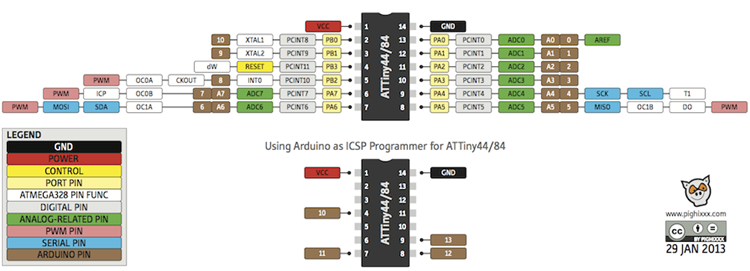

const int XaxisENCPinA = 2; // X-AXIS encoder 1 on pins 2 and 4

const int XaxisENCPinB = 4;

const int XaxisENDSTOP = 10; // Endstop photointerrupter for X-Axis

volatile double XaxisENCPos = 0;

const int YaxisENCPinA = 3; // Y-AXIS encoder 2 on pins 3 and 5

const int YaxisENCPinB = 5;

const int YaxisENDSTOP = 11; // Endstop photointerrupter for Y-Axis

volatile double YaxisENCPos = 0;

double XaxisSpd, YaxisSpd; // Carriage speed from 0-255

double XaxisPos, YaxisPos; // Current Carriage position

/*working variables for PID routines*/

// Tuning parameters

float KpX=0, KpY=0; //Initial Proportional Gain

float KiX=10, KiY=10; //Initial Integral Gain

float KdX=0, KdY=0; //Initial Differential Gain

double XaxisSetpoint, YaxisSetpoint; // Taget position for carriage

// Instantiate X and Y axis PID controls

PID XaxisPID(&XaxisPos, &XaxisSpd, &XaxisSetpoint, KpX, KiX, KdX, DIRECT);

PID YaxisPID(&YaxisPos, &YaxisSpd, &YaxisSetpoint, KpY, KiY, KdY, DIRECT);

const int sampleRate = 1;

long int reportTime;

void setup() {

Serial.begin(115200);

Serial.println("Linear Encoder Test 05-12-2014");

AFMS.begin(); // Set up Motors

XaxisMotor->run(BACKWARD); // Bring carriage to home position.

XaxisMotor->setSpeed(70);

delay(100); // Get endstop limiter working here

XaxisMotor->run(FORWARD); // Bring carriage to home position.

XaxisMotor->setSpeed(0);

YaxisMotor->run(BACKWARD); // Bring carriage to home position.

YaxisMotor->setSpeed(70);

delay(100); // Get endstop limiter working here

YaxisMotor->run(FORWARD); // Bring carriage to home position.

YaxisMotor->setSpeed(0);

attachInterrupt(0, doXaxisENC, CHANGE); // encoder pin on interrupt 0 (pin 2)

attachInterrupt(1, doYaxisENC, CHANGE); // encoder pin on interrupt 1 (pin 3)

PCintPort::attachInterrupt(XaxisENDSTOP,doXaxisEndstop,FALLING); //X-axis Endstop ISR

PCintPort::attachInterrupt(YaxisENDSTOP,doYaxisEndstop,FALLING); //Y-axis Endstop ISR

randomSeed(analogRead(0)); // Used to select random setpoints for testing

XaxisPID.SetMode(AUTOMATIC); //Turn on the PID loop

XaxisPID.SetSampleTime(sampleRate); //Sets the sample rate

YaxisPID.SetMode(AUTOMATIC); //Turn on the PID loop

YaxisPID.SetSampleTime(sampleRate); //Sets the sample rate

reportTime = millis()+2000;

}

void loop() {

uint8_t oldSREG = SREG; // Store interrupt status register

cli();

XaxisPos = XaxisENCPos;

YaxisPos = YaxisENCPos;

SREG = oldSREG; // Restore interrupt status register

// Temporary to create random X and Y axis setpoints for testing

if(millis() > reportTime) { // Only validate this every 2 seconds

if(XaxisPos == XaxisSetpoint && YaxisPos == YaxisSetpoint) {

// If both X-axis and Y-axis have reached their target - get new targets

XaxisSetpoint = random(200,3500); // Keep target within bounds of Endpoints

YaxisSetpoint = random(200,3500); // Keep target within bounds of Endpoints

}

reportTime = millis()+2000;

}

// Manage X-axis positioning

XaxisPID.Compute(); //Run the PID loop

if(XaxisSetpoint < XaxisPos) XaxisMotor->run(BACKWARD); // Determine direction of travel

else XaxisMotor->run(FORWARD);

XaxisMotor->setSpeed(XaxisSpd); // Apply PID speed to motor

// Manage Y-axis positioning

YaxisPID.Compute(); //Run the PID loop

if(YaxisSetpoint < YaxisPos) YaxisMotor->run(BACKWARD); // Determine direction of travel

else YaxisMotor->run(FORWARD);

YaxisMotor->setSpeed(YaxisSpd); // Apply PID speed to motor

}

/***************************************************************************************

The following code was taken from http://forum.arduino.cc/index.php?topic=41615.20;wap2

to utilize the fast port based encoder logic. Thank you Lefty!

please go there for a full explanation of how this works. I have truncated the comments

here for brevity.

***************************************************************************************/

void doXaxisENC() { // ************** X- AXIS ****************

if (PIND & 0x04) { // test for a low-to-high interrupt on channel A,

if ( !(PIND & 0x10)) { // check channel B for which way encoder turned,

XaxisENCPos = ++XaxisENCPos; // CW rotation

}

else {

XaxisENCPos = --XaxisENCPos; // CCW rotation

}

}

else { // it was a high-to-low interrupt on channel A

if (PIND & 0x10) { // check channel B for which way encoder turned,

XaxisENCPos = ++XaxisENCPos; // CW rotation

}

else {

XaxisENCPos = --XaxisENCPos; // CCW rotation

}

}

} // End of interrupt code for encoder #1

void doYaxisENC(){ // ************** X- AXIS ****************

if (PIND & 0x08) { // test for a low-to-high interrupt on channel A,

if (!(PIND & 0x20)) { // check channel B for which way encoder turned,

YaxisENCPos = ++YaxisENCPos; // CW rotation

}

else {

YaxisENCPos = --YaxisENCPos; // CCW rotation

}

}

else { // it was a high-to-low interrupt on channel A

if (PIND & 0x20) { // check channel B for which way encoder turned,

YaxisENCPos = ++YaxisENCPos; // CW rotation

}

else {

YaxisENCPos = --YaxisENCPos; // CCW rotation

}

}

} // End of interrupt code for encoder #2

void doXaxisEndstop() {

XaxisENCPos=0; // X-Axis Endstop indicates ZERO position

}

void doYaxisEndstop() {

YaxisENCPos=0; // Y-Axis Endstop indicates ZERO position

}